To a craftsman, understanding the raw materials he or she works with is an integral part of the job. A craftsman molds raw materials into something that fits their vision and at times can be a perfect mix of both artistic flair and industrial functionality.

In the woodworking world, and at McClure Tables, the terms “end grain” and “edge grain” are common used terminologies that may not mean much to some, but are a part of our every day lives. Let’s take a deeper dive into the wood that goes from a tree to a table and how we use different parts for different McClure handcrafted products.

Trees are generally cut into planks of wood. When constructing a butcher block or shuffleboard table tops, we must decide which of the planks sides will face up or act as the surface. We generally use the end or the edge of the grain.

Below we’ll take a in-depth look at each cut in order to explore the differences between end grain vs. edge grain:

What Is End Grain?

End grain boards are the part of the tree that is cut horizontally across the tree like a sawed off tree trunk where the grain will be open for the top of your board or chopping block. End grain is usually the most expensive because it is the most labor intensive to make. You first have to glue up an edge grain block then slice off the pieces to stand on their end and repeat the glue up process a second time.

This will make the edge grain block that will create a checkerboard pattern with a beautiful and distinct color variant. Traditional butcher’s blocks are end-grain construction. We use end grain wood for chopping blocks, kitchen islands, gathering blocks, kitchen carts… anything that requires a level of high durability in the kitchen. These extremely tough ends are able to easily withstand sharp edges as the wood fibers are pointing upwards and you are cutting into the fibers instead of across them as on edge grain. The knife edge spreads the fibers apart and they mend back together thus putting less pressure on the knife edge to keep it sharper longer and the wood also retains less deep knife marks.

End grain blocks tend to be heavier because they are thicker and the wood is harder so it is slightly more difficult to sand and restore vs. edge grain.

Main Uses: Cutting Boards, Gathering Blocks, Chopping Blocks and Kitchen Carts.

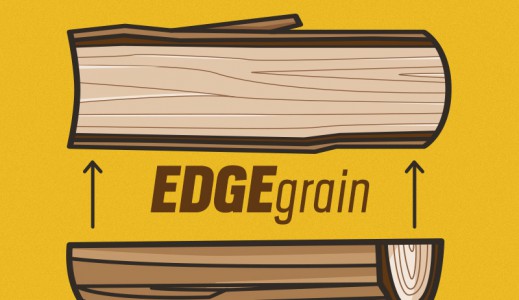

What Is Edge Grain?

Edge Grain boards are the section of the tree that is cut vertically down the trunk of the tree (which is how the saw mill will process raw lumber). When we are crafting our renowned butcher block products like shuffleboard tops and kitchen counter tops from edge grain, we first rip the raw lumber to the width of the end thickness then lay the wood rail on their edges (the shorter of the wood strips two sides is it’s edge and the longer side being it’s face).

We will actually glue the wider face sides together and create an amazingly beautiful and strong surface. You have two types of edge grain butcher block; construction blended and continuous rails. Our shuffleboard tops are almost always blended. However, for counter tops, generally the wood strips run the entire length of the board. This is because butcher block that uses continuous rail edge grain will have no unattractive butt ends or finger joints and will have a more consistent color throughout. Butcher blocks that are made from edge grain are also more utilitarian and industrial in nature, however, they do tend to show cuts and scratches more easily than it’s end grain counterpart. Despite this slight weakness, restoration of edge grain products are simple to perform and easily attainable.

Main Uses: Kitchen Carts, Kitchen Islands, Kitchen Counters.

In summary, the different methods of cutting wood harvest from a tree and the end material it yields makes a big difference in durability, look, and overall purpose when creating butcher blocks from scratch. Each have their own pros and cons but it’s our job as craftsman to understand what each grain is best suited for when creating our butcher block products.